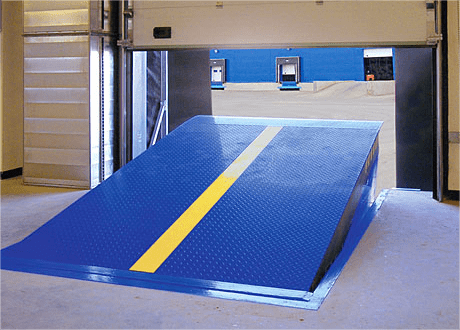

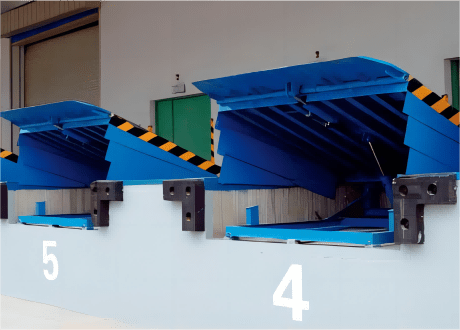

Stationary Loading Ramp

High-Strength, Integral Axle Connection, Modular Hydraulic Station

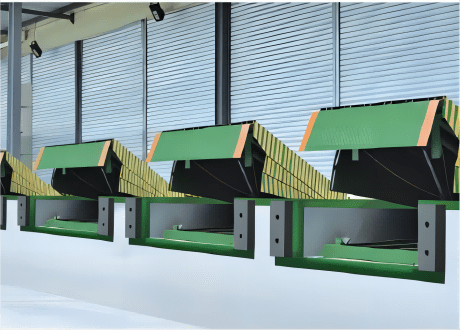

A Dock Leveler is a piece of equipment commonly found in loading docks or warehouses. Its purpose is to bridge the gap between a truck and the loading dock floor, allowing forklifts and other equipment to move smoothly between the two surfaces during the loading and unloading of goods.Dock levelers typically consist of a platform that can be raised or lowered to match the height of the truck bed. This adjustment helps to create a level surface for safe and efficient loading and unloading operations.

Models & Specs

| Model | DCQG-6T | DCQG-8T | DCQG-10T | |||

| Workbench Size | 2000*2000mm | 2000*2500mm | 2000*2000mm | 2000*2500mm | 2000*2000mm | 2000*2500mm |

| Loading Capacity | 6000KG | 6000KG | 8000KG | 8000KG | 10000KG | 10000KG |

| Tilt Up | 400mm | 450mm | 400mm | 450mm | 400mm | 450mm |

| Tilt Down | 300mm | 300mm | 300mm | 300mm | 300mm | 300mm |

| Dimensions (L*W*H) | 2000*2000*600mm | 2000*2500*600mm | 2000*2000*600mm | 2000*2500*600mm | 2000*2000*600mm | 2000*2500*600mm |

| Total weight | 640KG | 720KG | 700KG | 800KG | 710KG | 830KG |

| Power | 1.1kW | 1.1kW | 1.1kW | 1.1kW | 1.1kW | 1.1kW |

| Power supply rated voltage | 380V | 380V | 380V | 380V | 380V | 380V |

Custom Options

Customize Your Lifts

Specifically sized, configured, mobile, high-cycle, or automated – when you need a lift to perform a specific function, we have the materials, components, and design techniques to produce a one-of-a-kind lifting solution for your application.

Structure & Features

Structure

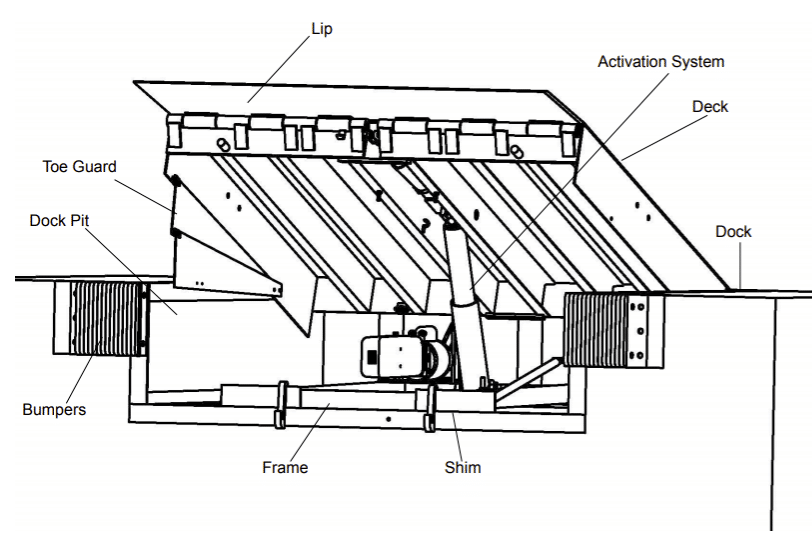

Activation System

This is the system designed to put the dock leveler into operation. The three most common activation systems are mechanical, pneumatic, and hydraulic.

Bumpers

Typically made of rubber, bumpers are used to prevent the trailer from bumping into and damaging the building, dock leveler or vehicle restraint.

Deck

The deck, or deck assembly, is the part of the dock leveler structure that the forklift drives over. Decks usually have an anti-skid surface such as a tread plate surface that provides traction for the forklift. At one end of the deck is a hinged lip. The back end of the deck, the end furthest from the truck, pivots.

Dock

The area of a building where trailers load and/or unload their cargo.

Dock Level

The vertical level that conforms to the building’s floor surface.

Dock Pit

The recessed opening in the dock’s concrete floor accommodates the pit dock leveler. They are usually lined along the edges with structural steel angles embedded in the concrete.

Frame

Also known as the frame assembly. This is the supporting structure for a dock leveler.

Lip

Also known as the lip assembly, the lip is usually pivotally attached to the deck assembly. It pivots from a vertical stored position to a position that rests on the trailer’s floor. Lips usually have a tread plate that is similar to the deck.

Shim

The steel plates that can be used to help level pit-mounted dock levelers. They can be put under the frame structure and welded in place to create a structural load path to the building’s foundation.

Features

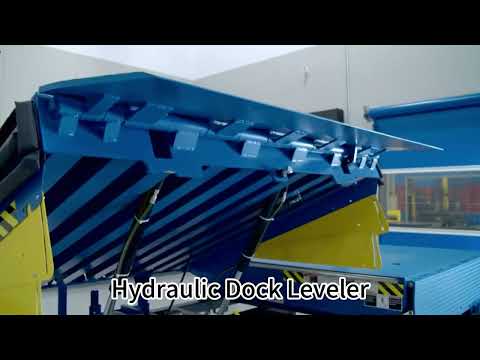

Fully Hydraulic Drive

Utilizes a complete hydraulic drive system for convenient operation and reliable performance, ensuring smooth lifting and lowering.

Integral Axle Connection

The lip plate and platform are connected with integral axles, enhancing strength and reliability, ensuring deformation-free operation over extended periods.

Imported Seals

Incorporates imported seals to guarantee excellent sealing performance of the hydraulic system, enhancing stability and durability.

Imported Modular Hydraulic Station

Utilizes an imported modular hydraulic station, providing superior sealing and long service life, improving equipment reliability and maintenance efficiency.

High-Strength Design

Features a high-strength “U” beam design to maintain structural integrity and stability under heavy loads for prolonged periods, ensuring a safe working environment.

Anti-Skid Design

Equipped with anti-skid pattern steel plates on the platform for enhanced traction and safety during operation.

Safety Features

Includes side skirts to prevent foot entrapment accidents, and support rods for ensuring the safety of maintenance personnel when entering the loading bridge interior.

| LIFT CAPACITY | |

|---|---|

| PLATFORM WIDTH | 1 – 2 m |

| PLATFORM LENGTH | 1 – 3 m |

| TRAVEL DISTANCE | 1 – 3 m |