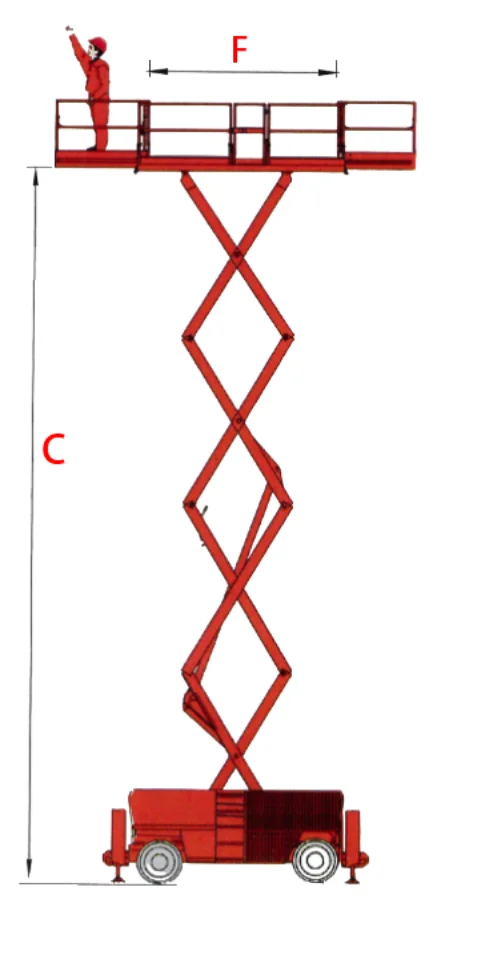

6m Self-Propelled Electric Scissor Lift

2.01 × 0.83m, Electric Control, Hydraulic, Self Propelled, With Wheels

Electric drive delivers more than double the battery life of hydraulic-drive machines.

Available with various working heights and platform capacities, it’s easy to find a mobile scissor lift model to fit the needs of your job site.

Models & Specs

| Attribute | Value |

|---|---|

| Model | G-SJY0.5-6 |

| Platform Size (mm) | 2010 × 830 |

| Lift Height (m) | 6 |

| Load Capacity (kg) | 500 |

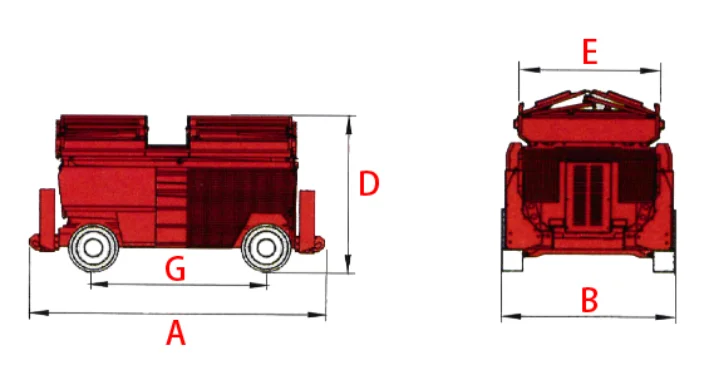

| Folded Dimensions (mm) | 2016 × 1000 × 1170 |

| Self-weight (kg) | 730 |

Features

Videos

Size Chart

Main Component Introduction

Chassis Assembly

The chassis assembly consists of the track assembly, welded track chassis, fuel tank, hydraulic components of the power unit, battery, and other related hydraulic and electrical components. The travel method is motor-driven, and the track material is rubber, meeting the vehicle’s travel requirements in different environments. When traveling on ramps, the driving mechanism has a self-braking function. The steering mechanism uses a motor to drive the track steering system in both directions, enabling the machine to have an ultra-compact turning radius suitable for narrow environments.

Boom Assembly

The boom assembly employs a scissor arm mechanism, allowing for more flexible movement and improved work efficiency. High-strength materials are used, reducing the overall weight of the scissor arm assembly and enhancing the machine’s stability.

Electrical System

The electrical system uses a control system provided by Shanghai Lezhan, employing CAN bus control technology. The chassis and platform have separate control panels, and the platform is equipped with a display. Communication between the chassis and platform controllers is achieved via the CAN bus, allowing control of machine movements. The electrical system’s main functions include controlling the chassis’s steering and travel. Safety measures include: an integrated tilt sensing device in the control system, which limits the machine’s ascent and travel on hazardous surfaces; a load alarm system that triggers an alert if the safe load is exceeded; an integrated interlock switch on the handle to prevent accidental activation; and the machine cannot travel when in an elevated position.

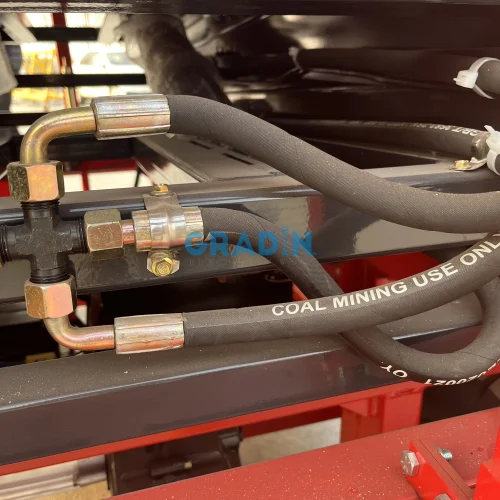

Hydraulic System

The hydraulic system is pump-driven, powered directly by the battery. The hydraulic assembly uses components provided by Hydraforce in the USA, and the hydraulic system employs electro-hydraulic proportional control technology to ensure smooth operation of the machine’s movements. The travel function has both high and low-speed settings. The lift cylinder is equipped with a buffering mechanism for smooth descent in the final segment; a balance valve on the cylinder ensures that it does not descend automatically during a hydraulic hose rupture. The machine’s cylinder is equipped with an emergency lowering valve, allowing the platform to descend at a controlled speed during unexpected failures or power loss, ensuring personnel safety.

Custom Options

Customize Your Lifts

Specifically sized, configured, mobile, high-cycle, or automated – when you need a lift to perform a specific function, we have the materials, components, and design techniques to produce a one-of-a-kind lifting solution for your application.

Features & Benefits

Safety Certification

Compliant with the European EN280 standard and CE certified.

Walking at Aerial Work

It has the function of automatic movement, capable of walking at different speeds in various working conditions. With just one person, it can perform continuous lifting, forward, backward, and turning actions during high-altitude operations. This significantly improves work efficiency compared to traditional hydraulic platforms, reducing the number of operators and labor intensity.

Safety Protection

The machine is equipped with a horizontal alarm device. When the vehicle tilts beyond the safe angle, the machine automatically enters the protection system, allowing only the downward movement of the machine. After reaching a safe state, it can be used normally. Each cylinder is equipped with an oil pipe explosion-proof system to prevent rapid descent due to external force damage.

Stepless Speed Control

With only one operator, all actions are controlled using the operating handles on the work platform. The motor adopts stepless speed control, effectively extending the lifespan of batteries and motors, with the motor consuming energy only during operation. The walking hydraulic system adopts a closed-loop variable pump control system, effectively improving system efficiency. Regardless of the position of the boom, the work platform can walk safely; the walking speed decreases as the lifting height increases.

Control system

Utilizes metal waterproof plugs, suitable for charging voltages in various countries, with a protection rating reaching IP65. It also adopts advanced CAN bus control, with simple and reliable wiring; equipped with self-diagnostic function, allowing customers to quickly grasp the equipment’s own working status for better maintenance. Emergency stop buttons are installed on both upper and lower control panels, allowing operators to quickly cut off all actions in case of accidents, preventing the platform from continuing to move.

Disk Brake System

Adopts a hydraulic disk brake system, with the wheels always in a braking state when the machine is stopped, and reliable braking on a 6-degree slope.

Extension Platform

The platform can be extended, expanding the working range to meet the special needs of some users.

Overload Protection

Equipped with overload protection function, providing mandatory protection for personnel unfamiliar with the equipment.

Product Documents

| LIFT CAPACITY | |

|---|---|

| PLATFORM LENGTH | 1 – 3 m |

| PLATFORM WIDTH | ≤ 1 m |

| TRAVEL DISTANCE | 5 – 7 m |