POSTED: 12/4/2024

Usage

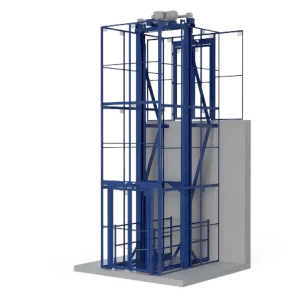

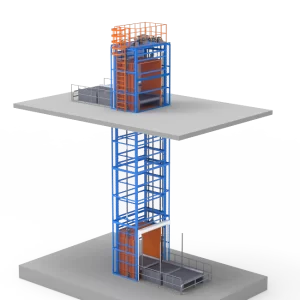

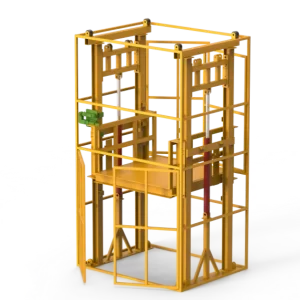

Primarily used for lifting raw materials in the clean workshops of pharmaceutical companies, the entire machine has been treated for cleanliness and meets the requirements of relevant departments for use in Class 300,000 cleanroom GMP workshops.

Our Solution

- Platform and space dimensions:

- Platform size: 1000mm x 1000mm

- Space size: 1800mm x 1300mm

- Travel and direction:

- In-out direction: 1000mm through access

- Travel height: 2200mm

- Load capacity and stops:

- Rated load: 500kg

- Stops: 2 stops at 2 stations

- Structure and materials:

- Equipment grade: Standard

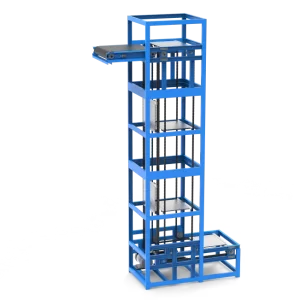

- Structural form: 2 cylinders, 4 tracks

- Material standards:

- Guide rail: H100

- Cylinder specifications: Φ50-35

- Lifting frame: 160mm x 60mm x 4mm

- Raising frame: 120mm x 60mm x 4mm

- Platform and panel materials:

- Platform frame: 80mm x 80mm square pipe or workshop stainless steel scrap

- Platform panel: 2.5mm thick 304 stainless steel sheet

- Other components:

- Pump station: 3 kW

- Chain: Stainless steel

- Steel wire rope: 12#

- Landing doors: 2 sets

- Pit: No pit

- Entry ramp: Not specified in detail

Additional Equipment Requirements

- Overall Machine Requirements:

- The entire machine should be enclosed with 2mm thick 304 stainless steel.

- The total height of the machine must not exceed 4100mm, considering the site floor-to-ceiling height of 4100mm.

- Platform Frame and Railings:

- The platform frame should be made of 304 stainless steel rectangular tubing.

- Safety railings on both sides of the platform should be 0.8 meters high and made of 304 stainless steel.

- Chain:

- Made of stainless steel.

- Landing Doors:

- 2 sets of center-opening doors, with a total height of 1.5 meters and a total width of 1.6 meters.

- Doors should feature an interlock that cuts power when opened.

- Made from 304 stainless steel square tube and 304 stainless steel sheet, as referenced in the design drawings.

- Packaging:

- Due to the long transportation distance, it’s crucial to pack stainless steel sheets and other fragile components securely to avoid damage and the potential costs of replacements.

- Production Considerations:

- The installation will occur on a steel platform inside the workshop, which offers an open space environment.

- Only transportation dimensions need to be considered during design and fabrication.

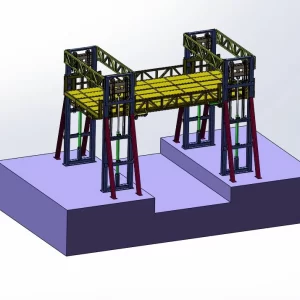

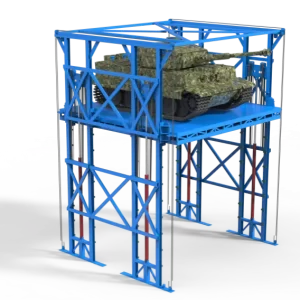

Related Freight Lift Products

Other Freight Lift Cases

If you want to customize your material handling equipment, please contact us.