RESOURCE CENTER > CASE STUDIES

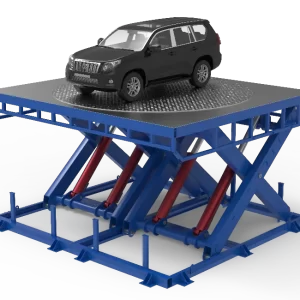

Autonomous Vehicle Testing Calibration Rotating Platform

POSTED: 1/10/2024

Project Overview

The client is a leading smart logistics and supply chain solutions company in China.

This system utilizes a servo motor for high-precision rotation, primarily applied in two phases of unmanned vehicle manufacturing: first, during the post-production testing phase, and second, in the design phase for calibrating the first prototype vehicle.

Basic Parameters

| Specification | Details |

|---|---|

| Model | BXZ5.0-5.0 |

| Rotating Platform Diameter | 5000 mm |

| Required Space Diameter | 5100 mm |

| Platform Flatness | ≤ ±4 mm |

| Platform Roundness | ≤ ±3 mm |

| Maximum Speed | 1 r/min |

| Minimum Speed | 0.167 r/min |

| Equipment Height | 700 mm |

| Installation Method | Indoor, 700 mm pit installation, flush with ground |

| Step Angle | 10° (Error ≤ ±0.5°) |

| Rated Load | 5000 kg |

| Equipment Weight | 4100 kg |

| Full Load Ground Load | 464 kg/m² |

| Working Environment | Indoor |

| Operating Temperature | -20°C to 60°C |

| Working Voltage | 380V/AC/50Hz |

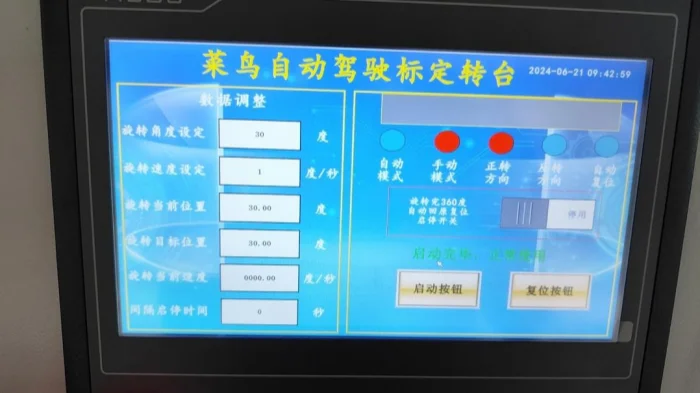

| Operation Panel | 10-inch local touchscreen |

| Control Cabinet Buttons | Illuminated buttons |

| Control Panel | PLC |

| Motor Brand | Siemens |

| Motor Type | Stepper Motor (Pulse Motor) |

| Surface Treatment | Painted or powder-coated |

| Rotation Direction | ±360° |

| Operating Mode | Step 10° every 10 seconds (adjustable) |

| Rotation Direction Setting | ± |

| Rotation Speed Setting | 1 to 6 minutes per rotation |

| Rotation Angle Setting | Integer multiples of 10° |

| Response Speed | ≤ 0.5 s |

| Arbitrary Start/Stop | Yes |

| One-Key Reset | Automatic reset with one button |

| Smooth Start/Stop | Program-controlled smooth start and stop |

| Emergency Stop | Controlled by emergency button |

| Overload Protection | Controlled by overcurrent relay |

Related Products

If you want to customize your equipment, please contact us.