RESOURCE CENTER > CASE STUDIES

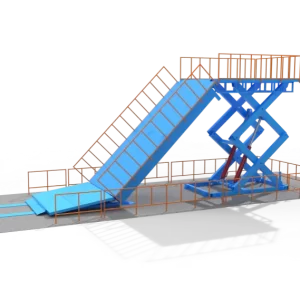

Stationary Hydraulic Vehicle-Ride Bridge for Pump Manufacturing Company

POSTED: 10/31/2024

Uses and Scenarios

This loading dock is primarily used for loading and unloading heavy materials between the production facility and transport vehicles. With its 10,000kg load capacity, the dock can easily accommodate large pumps and their components, ensuring safe and stable handling during loading and unloading.

In daily operations, operators can use the loading dock to move heavy pumps directly from the production line to trucks or cargo vehicles, allowing for quick and efficient loading. This process not only improves loading and unloading efficiency but also reduces the risk of injury associated with manual handling of heavy items.

Additionally, the design of the loading dock makes it suitable for various types of transport vehicles, facilitating material transfer between multiple loading points. In warehouse management, this loading dock can also be used to transport finished pumps to storage areas, preparing them for subsequent distribution. Therefore, this loading dock plays a vital role in the logistics and warehousing processes of the pump manufacturing company.

Technical Requirements

| Product Name | Stationary Hydraulic Vehicle-Ride Bridge |

| Size | 2000 x 2500mm |

| Pit size | 2030 x 2500 x 610mm |

| Height | 600mm |

| Lifting Height | Tilt Up 400mm, Tilt Down 300mm |

| Capacity | 10000kg |

| Explosive-proof Grade | Normal |

| Amount | 3 |

Comparative Advantages

- Load Capacity:

- Loading Dock: Maximum load capacity of 10,000kg, suitable for heavy pumps and large equipment.

- Other Solutions (e.g., Traditional Ramps): Typically have lower load capacities, often ranging from 5,000kg to 8,000kg, limiting the types and weights of items that can be handled.

- Loading and Unloading Efficiency:

- Loading Dock: Designed for rapid loading and unloading, allowing multiple entries and exits in a short period. Assuming each loading cycle takes 5 minutes, it can complete 12 cycles per day, transferring a total of 60,000kg of materials.

- Other Solutions: Traditional methods may require 10 minutes or more per cycle, reducing daily loading capacity to about 30,000kg, which represents more than a 50% decrease in efficiency.

- Safety:

- Loading Dock: Features a sturdy structural design that minimizes the risk of heavy items slipping or tilting, equipped with safety features to ensure operational safety.

- Other Solutions: Manual handling or using unstable ramps increases the risk of accidents, raising the likelihood of employee injuries.

- Space Utilization:

- Loading Dock: Compact design suitable for various transport vehicles, enabling efficient material transfer in limited spaces.

- Other Solutions: Traditional ramps or freight elevators may occupy more space, reducing the effective utilization of warehouse or production areas.

- Adaptability:

- Loading Dock: Can be flexibly adjusted to meet different transportation needs, suitable for various vehicle types and loading scenarios.

- Other Solutions: May lack adaptability for specific vehicles or situations, limiting operational flexibility.

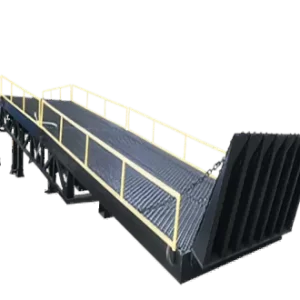

Related Loading Ramp Products

Other Loading Ramp Cases

If you want to customize your material handling equipment, please contact us.