RESOURCE CENTER > CASE STUDIES

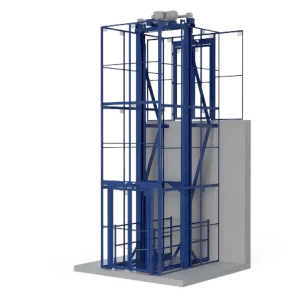

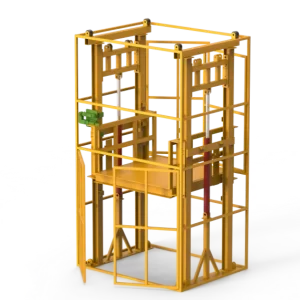

The SJD0.05-6 Reciprocating Lift For Food Industry Warehouses

POSTED: 13/2/2025

Usage

The SJD0.05-6 reciprocating lift is specifically designed for warehouse environments, suitable for transporting and elevating various packaged products, including fresh fruits, snacks, health drinks, seasonal fruits, and premium gift boxes. This equipment enhances operational efficiency and optimizes material flow within the warehouse, ensuring the safe and organized handling of products during storage and sorting.

Working Conditions

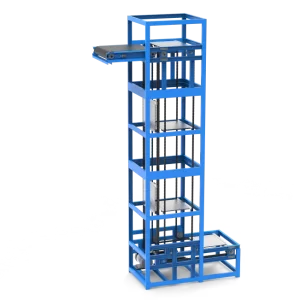

This lift is ideal for industrial settings like warehouses, capable of operating under stringent spatial and hygiene conditions. With a chain plate size of 700*700mm and a rated load of 50kg, it is suitable for handling light to medium-sized boxes. The lift features a vertical travel distance of 6000mm, meeting the needs for transporting materials to multiple levels of shelving. Constructed from aluminum alloy, it offers excellent corrosion resistance and lightweight properties, making it well-suited for long-term use in warehouse environments.

Solution

| No. | Specification | Details |

|---|---|---|

| 1 | Chain Plate Size | L700*W700mm (4 pieces) |

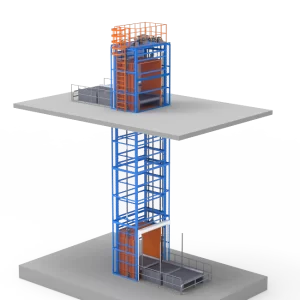

| 2 | Space Dimensions | 1600mm (in/out) * 1200mm |

| 3 | In/Out Direction | 1600mm direction, Z-type or C-type |

| 4 | Lifting Stroke | 6000mm |

| 5 | Rated Load | 50kg |

| 6 | Reduction Motor | 1.5kw |

| 7 | Control Method | PLC + Variable Frequency Drive |

| 8 | Cycle Time | ≤ 24s/item |

| 9 | Docking Stations | 2/2, 1 layer, 2 layers, Z-type in/out |

| 10 | Overall Coating | Spray paint/bake paint/powder coating (color customized per client request) |

| 11 | Installation Method | Installed and debugged by our professional personnel |

| 12 | Safety Design | – Emergency Stop: Equipped with an emergency stop button. – Under-voltage Protection: Prevents power supply to the motor to avoid damage. |

Advantages

- High Efficiency: Equipped with a 1.5kW reduction motor and controlled by a PLC and frequency converter, the lift ensures stable and efficient operation. The adjustable cycle time can reach ≤24s/item, allowing flexibility to meet various production demands and improve work efficiency.

- Safety Design: The equipment includes an emergency stop button for quick cessation of operation in emergencies, ensuring operator safety. Additionally, the control panel is equipped with a phase loss protection relay, which automatically enters a protective state when there is a phase loss, preventing motor damage.

- Flexibility: The lift allows for Z-type or C-type entry and exit, with space dimensions of 1600 (in-out) * 1200mm, adapting to different warehouse layouts and facilitating efficient material access.

- Professional Service: Our company provides professional installation and debugging services to ensure the equipment operates at optimal performance, reducing the maintenance burden on customers.

- Customizable Coating: The entire machine can be customized according to customer requirements, offering options for spray painting, baking paint, or plastic spraying to meet both aesthetic and practical needs.

- Durability: Made primarily of aluminum alloy, the lift is lightweight and corrosion-resistant, offering a better cost-performance ratio compared to stainless steel, making it ideal for long-term use in warehouses.

In summary, the SJD0.05-6 reciprocating lift, with its high efficiency, safety, and flexibility, is an ideal material handling solution for warehouses, helping customers enhance productivity and optimize workflows while ensuring the safe transportation of their products.

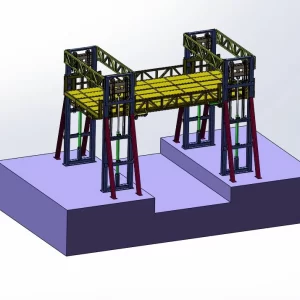

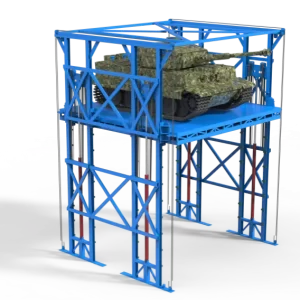

Related Freight Lift Products

Other Freight Lift Cases

If you want to customize your material handling equipment, please contact us.