How long should a scissor lift last

Home > Scissor Lift > How long should a scissor lift last

FAQ

Tags

4 Posts (1) Articulating Staircase (1) Automated (2) Automation (1) Battery Electric (2) Boom Lift (4) Compact Design (1) Diesel (1) Double Chain (1) Durability (2) Easy to use (1) Efficient Actuation (1) Explosion-Proof (1) Fast Installation (1) Fixed (3) Guide Rail (3) Heavy Duty (3) High-Strength (4) Hydraulic (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistics Equipment (1) Logistics Solutions (1) Maintenance Friendly (1) MEZZANINE (1) Mobile (1) Modular Design (2) Outdoor Lift (1) Production Line Solutions (1) Rigid Chain (1) Roller Chains (2) Safety (5) scissor lift (9) Self Propelled (3) Semi-Auto (1) Small (3) Stainless (1) Track-Mounted (1) Tracked (1) Vertical Lift (1) Vertical Transport (1) VRC (1) Warehouse Solutions (2) Weather Resistance (1)

How long should a scissor lift last

Scissor lifts are essential equipment in various industries, providing elevated access for tasks such as maintenance, construction, and warehousing. Understanding the lifespan of a scissor lift is crucial for businesses to plan for maintenance, repairs, and eventual replacement. Generally, a well-maintained scissor lift can last between 10 to 15 years. However, several factors influence this longevity.

1. Usage Frequency

The frequency of use plays a significant role in determining how long a scissor lift will last. Lifts that are used daily in high-demand environments will experience more wear and tear compared to those that are used only occasionally. Businesses that rely heavily on these lifts should be prepared for more frequent maintenance and potential replacements.

The following components of a scissor lift are most susceptible to wear:

Hydraulic System

Hydraulic hoses, cylinders, and pumps can develop leaks or performance issues due to prolonged use.

Tires

Tires are prone to wear, especially when used on rough or uneven surfaces.

Battery

The lifespan of batteries is limited, and frequent charging and discharging can lead to decreased performance.

Control System

Control panels and switches can wear out from frequent operation, resulting in unresponsive controls.

Safety Devices

Components like guardrails and emergency stop buttons may become damaged or fail over time.

Chassis

The chassis can suffer impacts during movement and load-bearing, potentially leading to deformation or damage.

2. Maintenance Practices

Regular inspections and maintenance are vital for extending the life of a scissor lift. Following the manufacturer’s recommended maintenance schedule can significantly enhance the lifespan of the equipment. This includes daily, monthly, and annual checks to ensure that all components are functioning correctly and safely. Neglecting maintenance can lead to premature wear and costly repairs.

3. Operating Conditions

The conditions under which a scissor lift operates can also impact its lifespan. Lifts used in harsh environments—such as extreme temperatures, high humidity, or rough terrains—are likely to experience more damage over time. Operators should consider these factors when planning the use of scissor lifts and may need to invest in more robust models for challenging conditions.

Lifts suitable for use in extreme temperatures, high humidity, or rugged terrain include:

All-Terrain Lifts

These lifts are equipped with all-wheel drive, providing better traction and stability on uneven surfaces.

Corrosion-Resistant Lifts

Made from materials like stainless steel or specialized coatings, these lifts can operate effectively in high-humidity or chemically corrosive environments.

Heated and Cooled Lifts

Some lifts come with heating or cooling systems to maintain optimal performance in extreme temperatures.

Waterproof Electrical Systems

Lifts with waterproof and dustproof ratings (such as IP65 or higher) are designed for safe operation in humid or rainy conditions.

Engineered for harsh conditions, these lifts can withstand greater loads and impacts, ensuring stability on rough terrain.

4. Quality of the Equipment

The quality of the scissor lift itself is another important factor. Higher-quality models from reputable manufacturers often utilize better materials and engineering practices, leading to a longer lifespan. Investing in a reliable lift may result in lower costs over time due to reduced maintenance and replacement needs.

Here are ten of the top scissor lift brands known for their quality, reliability, and innovation:

- Gradin

Gradin lifts are recognized for their quality and efficiency, with a focus on operator safety and comfort. - JLG Industries

A leader in aerial work platforms, JLG offers a wide range of scissor lifts known for their durability and advanced features. - Genie

Genie is renowned for its high-performance lifts, providing a variety of models suitable for different applications. - Skyjack

Known for their simplicity and ease of maintenance, Skyjack lifts are popular in the construction and maintenance industries. - Haulotte

This brand is recognized for its robust design and innovative features, making it a strong choice for various job sites. - Snorkel

Snorkel offers reliable and efficient scissor lifts, focusing on safety and user-friendly designs. - Manitou

Manitou is known for its versatile equipment, including scissor lifts that perform well in rugged conditions. - Niftylift

Specializing in compact, lightweight lifts, Niftylift is ideal for indoor and outdoor applications in tight spaces. - Bil-Jax

Bil-Jax provides a range of lifts that are durable and designed for tough job site conditions. - Lift-A-Loft

Known for its unique designs, Lift-A-Loft offers custom solutions for specific lifting needs.

5. Modifications and Repairs

Proper repairs and modifications can also extend the life of a scissor lift. Regularly addressing minor issues before they become major problems can prevent costly downtime and extend the overall lifespan of the equipment. Operators should keep detailed records of all maintenance and repairs to monitor the lift’s condition over time.

Conclusion

In summary, a scissor lift can typically last between 10 to 15 years with proper care and maintenance. Factors such as usage frequency, maintenance practices, operating conditions, equipment quality, and timely repairs all play crucial roles in determining its longevity. By adhering to maintenance protocols and using the lift within its intended parameters, businesses can help ensure that their scissor lifts remain safe and functional for years to come.

Top Rated Products

-

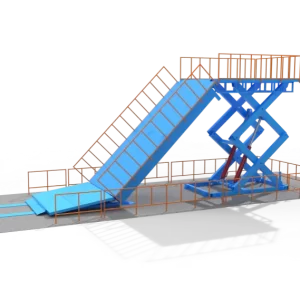

Loading Ramp With Scissor Lift

READ MORE2 – 3 ton

30˚ – 45˚

W : > 6 mL : > 11 m -

G-GTJZ16RT 16-meter Diesel Scissor Lift

READ MORE≤ 1 ton

> 11 m

W : 1 – 2 mL : 3 – 5 m -

G-GTJZ13RT 13-meter Diesel Scissor Lift

READ MORE≤ 1 ton

> 11 m

W : 1 – 2 mL : 3 – 5 m -

G-GTJZ10RT 10-meter Diesel Scissor Lift

READ MORE≤ 1 ton

9 – 11 m

W : 1 – 2 mL : 3 – 5 m -

CFPT1214LD 10m Tracked Scissor Lift

READ MORE≤ 1 ton

9 – 11 m

W : 1 – 2 mL : 1 – 3 m

Contact with our experts, or request a quote now.