Nacelles élévatrices électriques à bras articulé 18m

18.2m, 230/350kg, Compact in structure, Flexible in extension, Easy to use

Notre nacelle articulée G-V18 est conçue pour répondre à vos besoins en matière de travaux aériens les plus exigeants avec une efficacité et une précision inégalées. Avec une hauteur de travail maximale de 20,2 mètres, la G-V18 est idéale pour la construction, la décoration, les télécommunications, le placement de publicités et l'entretien des aéroports. Cet élévateur puissant et polyvalent offre des performances supérieures, des fonctions de sécurité avancées et une fiabilité exceptionnelle, ce qui en fait le premier choix des professionnels de divers secteurs. Parcourez les spécifications ci-dessous pour découvrir les capacités et les avantages impressionnants de la nacelle élévatrice à bras articulé G-V18.

Modèles et spécifications

| Spécifications | |

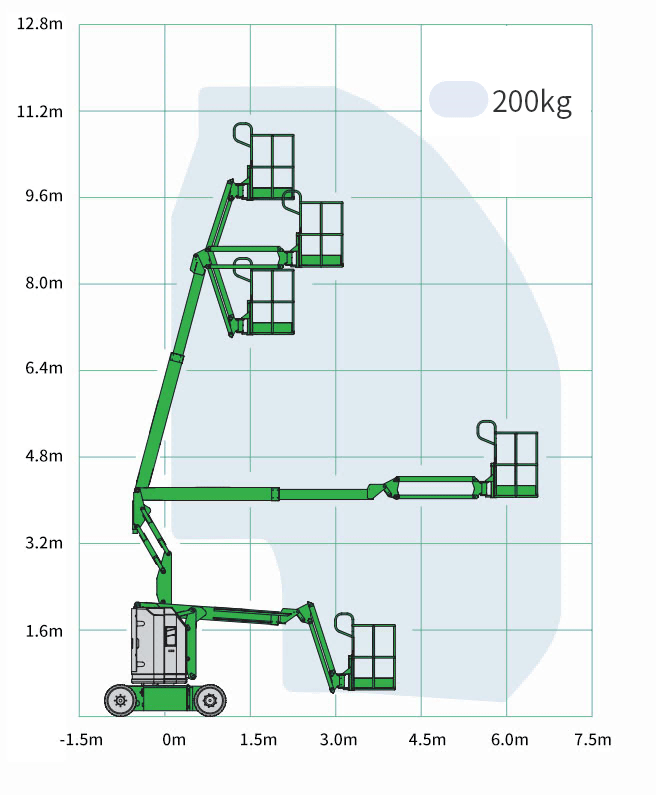

| Hauteur de travail max. Hauteur de travail | 20.2m |

| Max. Hauteur de la plate-forme | 18.2m |

| Dégagement maximal en amont et en aval | 8.0m |

| Max. Rayon d'action | 11.1m |

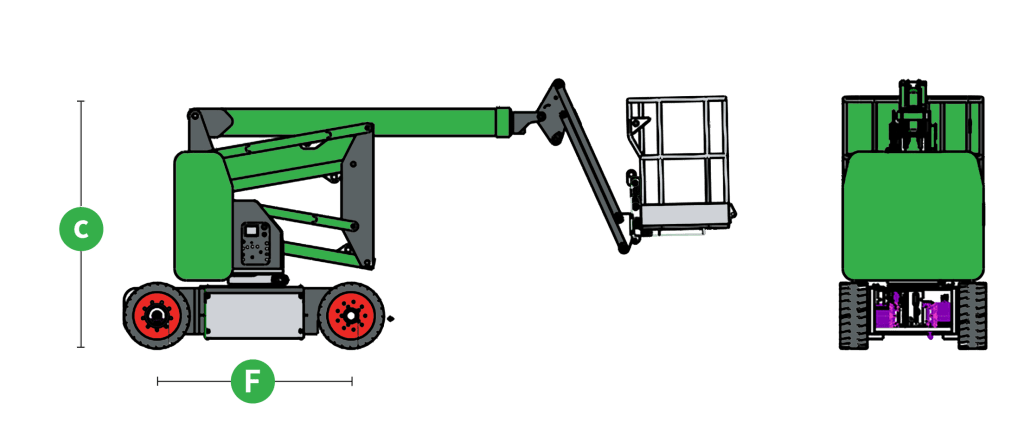

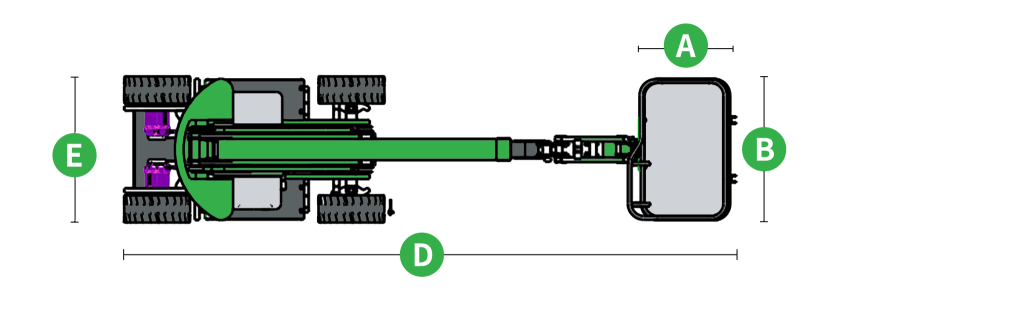

| Ⓐ Largeur de la plate-forme | 0.76m |

| Ⓑ Longueur de la plate-forme | 1.8m |

| Ⓒ Hauteur - rangée | 2.38m |

| Ⓓ Longueur - rangée | 8.49m |

| Ⓔ Largeur | 2.49m |

| Ⓕ Empattement | 2.5m |

| Garde au sol - centre | 0.3m |

| Productivité | |

| Capacité de levage max. Capacité de levage | 230kg/350kg |

| Nombre d'occupants de la plate-forme | 2/3 |

| Rotation de la plate-forme | ±80° |

| Rotation du plateau tournant | 360°Continuous |

| Vertical jib rotation (up/down) | ±70° |

| Vitesse d'entraînement - rangée | 4,8km/h |

| Pouvoir de nivellement - rangé | 45% |

| Angle de travail max. Angle de travail (activation du capteur d'inclinaison) | 3° |

| Rayon de braquage (extérieur) | 5.0m |

| Conduire et diriger | 4×2 |

| Poids | 9100kg |

| Puissance | |

| Batterie | 48V/320Ah |

| Tension de contrôle | 24V |

| Moteur de la pompe | 4kw |

| Moteur d'entraînement | 3,3 kW |

Caractéristiques

Léger et économe en énergie, ce produit est compact et dispose d'une excellente autonomie.

La flèche en forme de Σ, avec une structure compacte et une extension flexible, peut réaliser un levage vertical et une extension horizontale, et a une forte capacité de franchissement d'obstacles.

La plate-forme rotative à 160° offre une plus grande plage de travail, tandis que le plateau tournant étroit et la disposition compacte améliorent l'efficacité du travail.

Le panneau de commande de la plate-forme est de marque PG et Bosch Rexroth, identique à la commande au sol. La conception conviviale et les facteurs de sécurité pris en compte garantissent des performances de travail fiables.

La chaîne de traînée de marque internationale de la flèche télescopique offre une protection de sécurité et des capacités de guidage pour les câbles à l'intérieur des flèches et prolonge la durée de vie des câbles.

Équipé de pneus solides, antidérapants et antidéflagrants, d'une durée de vie plus longue, il assure un fonctionnement stable et économe en main-d'œuvre.

Vidéos

Diagram

Other Boom Lifts

FAQ

Options personnalisées

Personnalisez vos ascenseurs

De taille spécifique, configuré, mobile, à cycle élevé ou automatisé - lorsque vous avez besoin d'un élévateur pour accomplir une fonction spécifique, nous disposons des matériaux, des composants et des techniques de conception pour produire une solution de levage unique pour votre application.

Lift Product Videos

Mallettes personnalisées

L'élévateur à piston SJD0.05-6 pour les entrepôts de l'industrie alimentaire

Plate-forme rotative d'essai et d'étalonnage de véhicules autonomes

Plate-forme de levage sous-marine de type ciseaux en acier inoxydable 316L

Ascenseur hydraulique efficace et stable pour relever les défis du chargement et du déchargement dans l'industrie du tabac

Machine de retournement de chaîne 3 tonnes pour pompe à double vis

Elévateur de charge en acier inoxydable 304 pour la manutention de matières premières pharmaceutiques

Élévateur à mouvement alternatif conçu pour le transport de litière pour chats

Ascenseur à piston vertical efficace : Solution sur mesure pour le transport en vrac dans l'industrie des piles au lithium

Plate-forme élévatrice en acier inoxydable 316 : Solution de transport automatisé pour les brasseries

Levée de marchandises automatisée pour les entrepôts sans personnel

Plate-forme élévatrice pour Graphite Material Company

Monte-charge pour une entreprise de technologie de purification de l'eau

| CAPACITÉ DE LEVAGE | |

|---|---|

| LONGUEUR DE LA PLATE-FORME | 1 - 3 m |

| LARGEUR DE LA PLATE-FORME | ≤ 1 m |

| DISTANCE DE DÉPLACEMENT | > 11 m |