Elektrolitikus cellák összeszerelési platformja

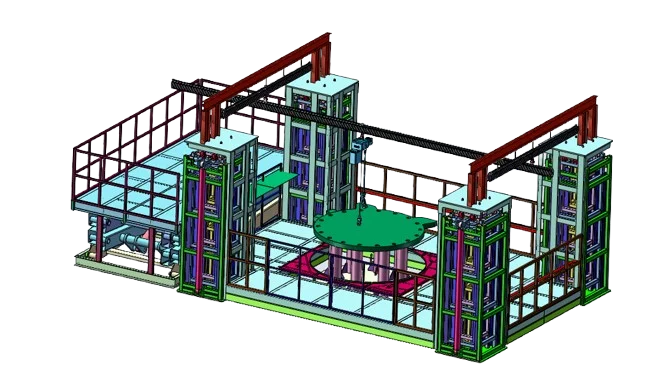

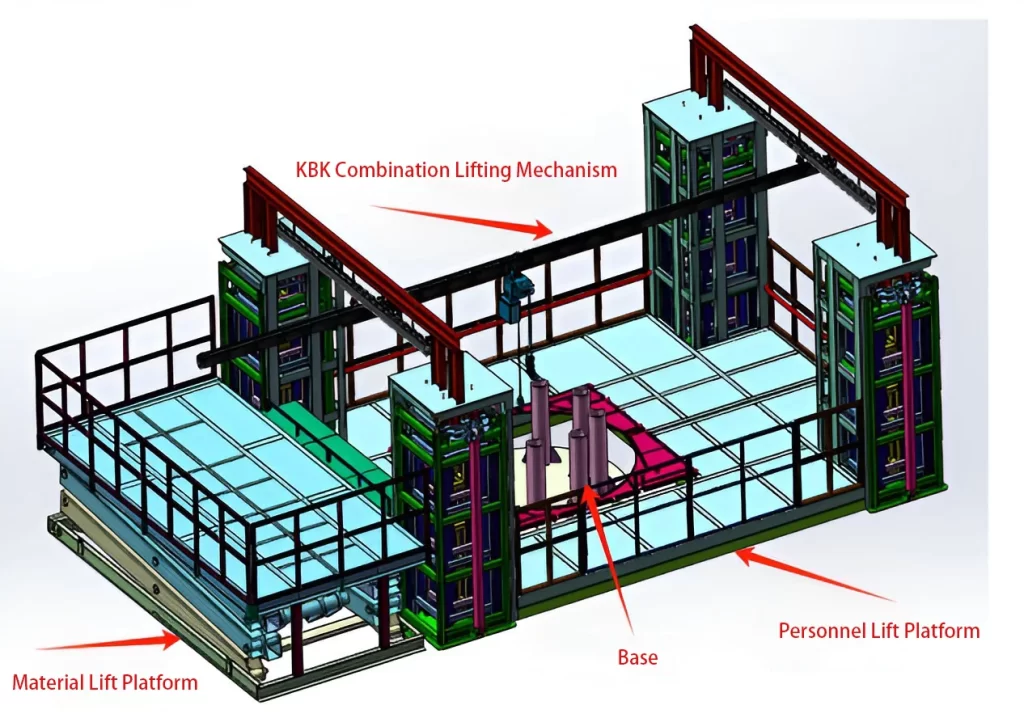

Solution 1 is designed for open areas and combines a personnel lift platform, KBK lifting mechanism, material lift platform, and electrolytic tank base to facilitate the installation process. The power specifications for each device are provided to ensure safe operation and a stable working environment.

Solution 2, on the other hand, is suitable for compact areas and consists of a cargo platform, personnel platform, and tilting machine. This solution is space-saving but requires more manual operation compared to Solution 1.

Modellek és specifikációk

| Product Name | Load Capacity | Minimum Height | Maximum Height | Table Size | Special Features |

|---|---|---|---|---|---|

| Personnel Lift Platform | 3 tons | 400 mm | 7000 mm | Customized per request | Four hydraulic cylinders for synchronous lifting |

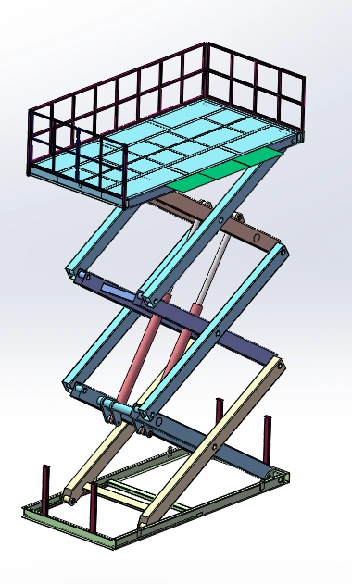

| Material Lift Platform | 3 tons | 1400 mm | 7000 mm | 5000 mm x 2500 mm | Mainly for transporting electrolysis tank components, easy assembly |

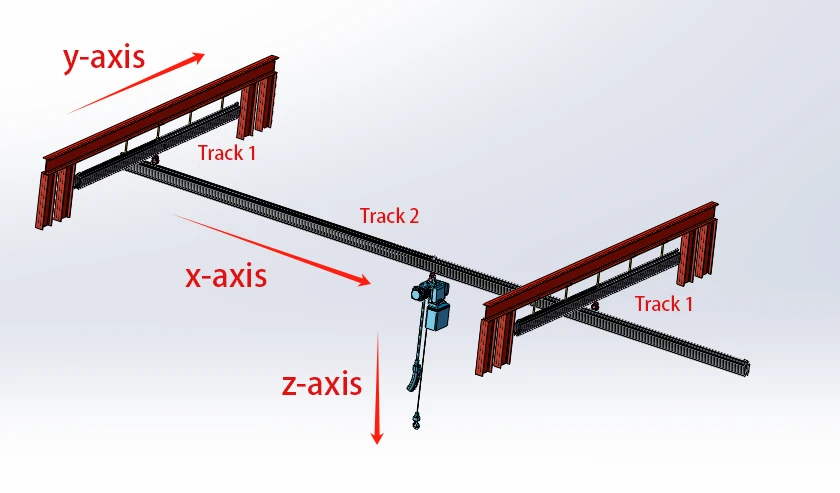

| KBK Combination Lifting Mechanism | 500 kg | – | 2500 mm | – | Hook can move in x, y, z directions |

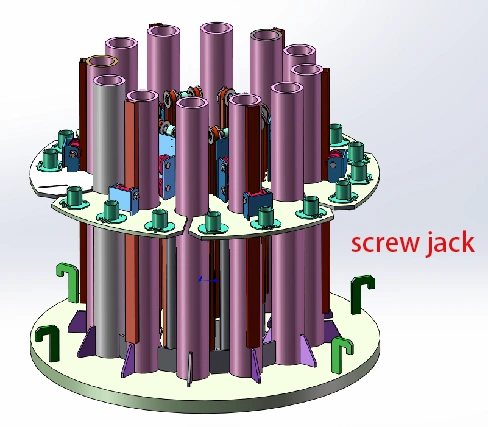

| Base | 60 tons | 1100 mm | – | Diameter 2300 mm | Available in fixed and adjustable types; adjustable base facilitates screw installation |

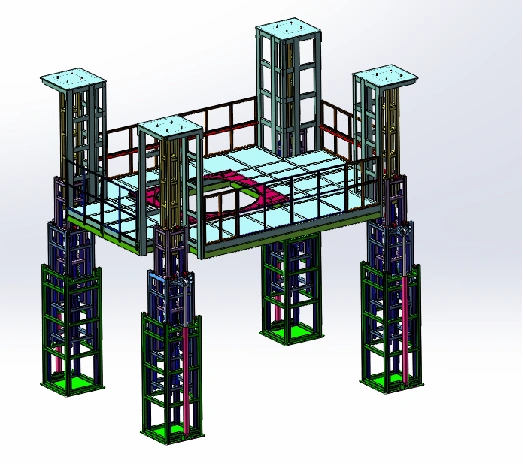

Personnel Lift Platform

Personnel Lift Platform Material Lift Platform

Material Lift Platform KBK Combination Lifting Mechanism

KBK Combination Lifting Mechanism Base

Base

Solution 1: Suitable for Open Areas

To meet the installation process for the electrolysis tank on site, our Assembly Platform contains a combination of the personnel lift platform, KBK lifting mechanism, material lift platform, and electrolysis tank base to complete the installation work.

The four sets of equipment are designed for different usage scenarios:

- The personnel lift platform provides a working platform for staff.

- The material lift platform is used for lifting the electrode plates.

- The KBK lifting mechanism is used for hoisting the electrode plates.

- The base is used to support the end plates of the electrolysis tank.

The power specifications for each device are as follows:

- Personnel lift platform: 7.5 kW

- Material lift platform: 7.5 kW

- KBK lifting mechanism: 1.1 kW

Electrolysis Cell Assembly Process

First, lower the manned lifting platform to its lowest position.

Before starting any operation, ensure that the manned lifting platform is lowered to its lowest position. This step is crucial for safety and provides adequate space and stability for the subsequent installation process.

Place the end plate of the electrolysis cell on the chassis.

Next, carefully position the end plate of the electrolysis cell onto the chassis. Ensure that the connection between the end plate and the chassis is smooth and secure to guarantee the overall stability and safety of the structure.

Install the anode plate, sealing gasket, diaphragm, bipolar plates, etc.

After securing the end plate, proceed to install the anode plate, sealing gasket, diaphragm, and bipolar plates in sequence. Make sure that each component is installed according to design specifications and check that their positions are accurate. Proper placement of the sealing gasket is particularly important to prevent any leakage of the electrolyte.

Finally, insert bolts to secure everything in place.

Once all components are installed, use bolts to secure the various parts together. Ensure that the bolts are tightened properly to enhance the overall sturdiness of the structure. Check all connection points to ensure there are no loose fittings, thereby improving the safety and reliability of the equipment.

Solution 2: Suitable for Compact Areas

This solution consists of three parts: a cargo platform, a personnel platform, and a tilting machine. Its features include space-saving design, but it requires more manual operation compared to Solution 1.

The operating steps are as follows:

- The wheeled movable cargo platform is moved above the electrolytic tank for assembly.

- After assembly is complete, the electrolytic tank is lifted and moved to the tilting machine.

- The tilting machine rotates the electrolytic tank 90 degrees to a horizontal position.

- The cargo platform is moved above the horizontal electrolytic tank to lift it.

- The cargo platform moves to the back of the truck to unload the electrolytic tank for transport.