Vertical Reciprocating Lifts

Home > Vertical Lifts > Vertical Reciprocating Lifts (VRC’s)

Product Catalog

MEGOLDÁSOK ALKALMAZÁS SZERINT

MI AZ ALKALMAZÁSOD?

Tervezési könyvtárunk és mérnöki képességeink lehetővé teszik számunkra, hogy megfeleljünk az Ön alkalmazási kihívásainak. Nem számít, milyen kihívást jelent, mi megépítjük a tökéletes felvonót, amire szüksége van.

MEGOLDÁSOK IPARÁGANKÉNT

MI AZ IPARÁGAD?

Mindenkinél jobban értjük az iparágspecifikus kihívásokat. A repülőgépgyártástól a kiskereskedelemig egyedülállóan alkalmasak vagyunk arra, hogy megértsük az Ön összes kihívását.

4 hozzászólás (1) Articulating Staircase (1) Automated (2) Automatizálás (1) Elektromos akkumulátor (2) Boom Lift (4) Compact Design (1) Diesel (1) Double Chain (1) Tartósság (2) Könnyen használható (1) Efficient Actuation (1) Robbanásbiztos (1) Gyors telepítés (1) Rögzített (3) Vezetősín (3) Nehéz teher (3) Nagy szilárdságú (4) Hidraulikus (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistics Equipment (1) Logisztikai megoldások (1) Karbantartásbarát (1) MEZZANINE (1) Mobil (1) Moduláris kialakítás (2) Kültéri felvonó (1) Production Line Solutions (1) Merev lánc (1) Görgős láncok (2) Biztonság (5) ollós emelő (9) Önjáró (3) Semi-Auto (1) Kis (3) Rozsdamentes (1) Pályára szerelt (1) Nyomkövető (1) Függőleges emelés (1) Függőleges szállítás (1) VRC (1) Warehouse Solutions (2) Időjárásállóság (1)

Vertical Reciprocating Lifts (VRC’s)

Vertical Reciprocating Conveyors (VRCs), also known as vertical lifts, are efficient for transporting materials to mezzanine floors. Unlike elevators, VRCs are not subject to strict elevator codes and regulations, as they are designed solely for moving materials and equipment—not passengers. This distinction allows for lower manufacturing and installation costs.

VRCs enhance safety compared to forklifts and other lifting methods, improving overall facility safety. For our VRC projects, Panel Built collaborates with dealers nationwide to provide customers with top-quality VRCs.

Alkalmazás

Anyagmozgatás

Perfect for transporting goods between different facility levels, our VRCs provide a reliable solution for moving heavy materials to mezzanines or upper floors.

Warehouse Operations

Our VRCs streamline the movement of pallets, boxes, and equipment within warehouses, optimizing space and increasing productivity.

Manufacturing Facilities

Ideal for transferring components and raw materials between production areas, our VRCs facilitate smooth workflows and help maintain operational efficiency.

Loading and Unloading

Designed to assist in loading and unloading trucks and containers, our VRCs reduce reliance on forklifts, enhancing safety and reducing operational costs.

Retail Environments

In multi-level retail spaces, our VRCs efficiently transport inventory from storage areas to sales floors, ensuring quick and organized restocking.

Food and Beverage Industry

Our VRCs are suitable for moving bulk materials and finished products in food processing and distribution centers, maintaining hygiene and safety standards.

Our Cases

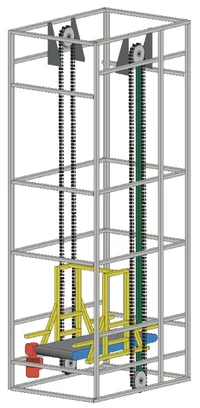

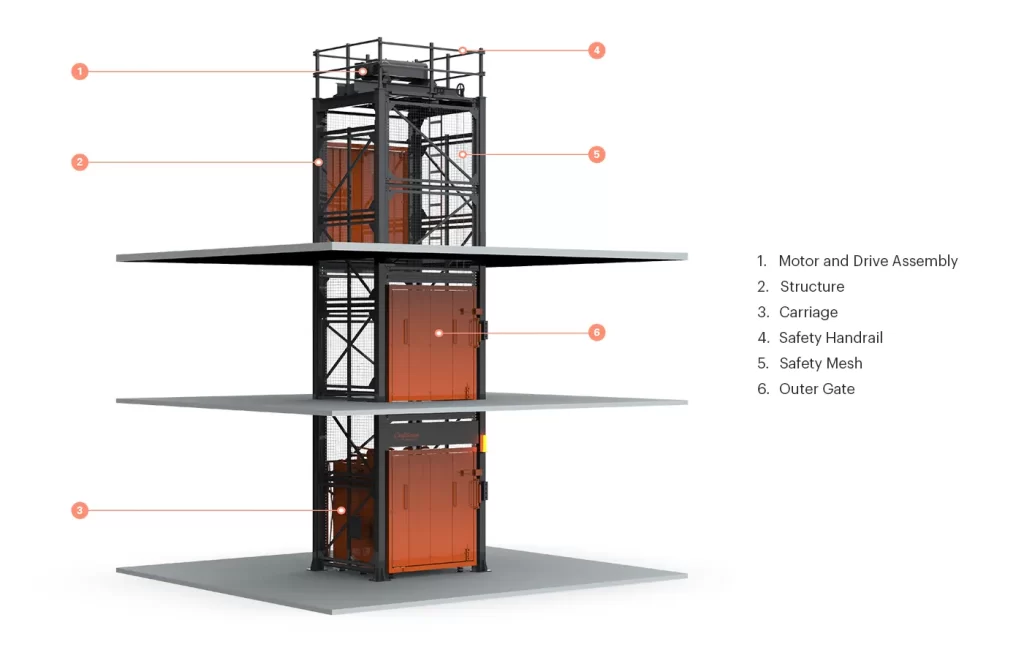

Key components

Drive System

Elektromos motor: Powers the lifting mechanism. Hidraulikus rendszer: Used in some models for smooth and efficient lifting

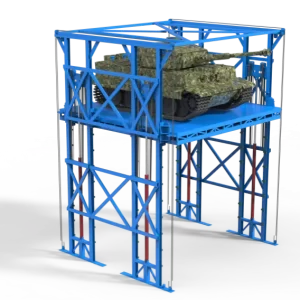

Lifting Platform

The surface on which materials are placed. Designed for stability and durability.

Guide Rails

Structures that keep the conveyor belt aligned and prevent materials from falling off.

Control Panel

User interface for operating the VRC, allowing for control of the lift’s movement (up, down, stop).

Biztonsági jellemzők

Overload Protection: Prevents lifting beyond the rated capacity.

Emergency Stop Button: Allows for immediate cessation of operation in case of emergencies.

Safety Locks: Engage when the platform is stationary to prevent accidental movement.

Support Structure

The framework that holds the entire system in place, ensuring stability and safety during operation.

Sensors

Detect the position of the platform and ensure safe operation by preventing collisions or over-travel.

Hydraulic Cylinders (if applicable)

Facilitate the lifting and lowering of the platform in hydraulic VRC models.

Top Rated Products

-

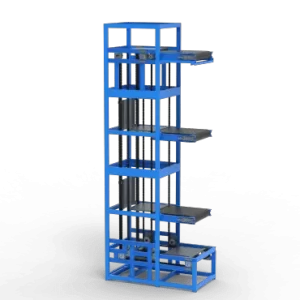

E alakú függőleges dugattyús szállítószalagok Lift

-

4 oszlopok Teljesen ketrecbe zárt teherlift

-

4 álláshelyes félemeleti árufelvonó

-

2 oszlopos falra szerelt teherlift

-

8 hozzászólás Cargo Lift

Modellek és specifikációk

| Modell | E alakú függőleges dugattyús szállítószalagok Lift |

| Lifting Capacity | 500 lbs to 20,000 lbs (Customized) |

| Lift Speed | Standard travel speed is 20 fpm. Higher speeds available. |

| Load/Unload Patterns | “E” pattern |

| Levels | 1 to 6 stops (Customized) |

| Power Supply | 230V/3P or 460V/3P |

| Alkalmazás | Moving heavy boxes, cargo, and pallets from one level to another. |