BRONNENCENTRUM > VIDEOS

Werkingsprincipe en werking van roltapijtliften

POSTED: 11/24/2024

Working Principle

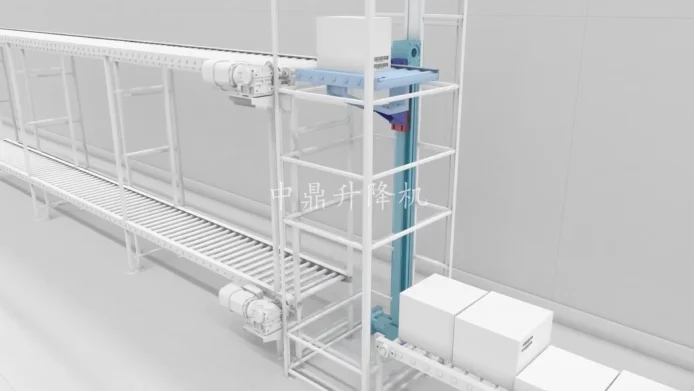

A roller conveyor lift is a system designed to transport materials vertically using a series of rotating rollers. The working principle is as follows:

- Power System: The conveyor lift is typically equipped with an electric motor that drives the rollers through a transmission mechanism (such as a belt or chain).

- Roller Structure: The conveyor consists of multiple independent rollers that can rotate freely. Materials are moved along the rollers by gravity or external force.

- Incline Angle: The rollers can be set at a specific incline to allow materials to ascend from a lower to a higher position smoothly.

- Lifting Mechanism: As the rollers rotate, they lift the materials along the designated path. At the top, materials can be discharged by gravity or transferred to other devices (such as chutes).

Operation

Material Feeding: Materials are placed on the rollers at the feeding point. Gravity or external pushing force initiates the movement of the materials.

Roller Rotation: The motor rotates the rollers, moving the materials upward along the conveyor path. The friction between the rollers and the materials helps keep the items in place.

Material Lifting: As the rollers rotate, materials are lifted to the desired height. The incline and speed of the rollers affect the lifting efficiency.

Material Discharge: When materials reach the top, gravity causes them to slide off into the unloading area or transfer to other devices (like chutes or belts).

Continuous Operation: After completing one cycle of material transport, the lift continues to receive new materials, creating a continuous operation.

The roller conveyor lift uses the rotation of rollers and the principle of gravity to achieve efficient vertical transport of materials. Its simple structure and effective operation make it widely used in logistics, warehousing, and manufacturing industries.

GERELATEERDE ONDERWERPEN