16m Electric Articulating Boom Lifts

15.7m, 230kg, Compact in structure, Flexible in extension, Easy to use

Our G-V16 Articulating Boom Lifts are the perfect solution for your mid-height aerial work needs. With a maximum working height of 17.7 meters, they excel in various applications such as construction, decoration, telecommunications, advertisement placement, and airport maintenance. This versatile and reliable lift offers superior performance and safety features, making it an excellent choice for professionals. Browse the specifications below to discover the impressive capabilities of the G-V16 Articulating Boom Lift.

Models & Specs

| Specifications | |

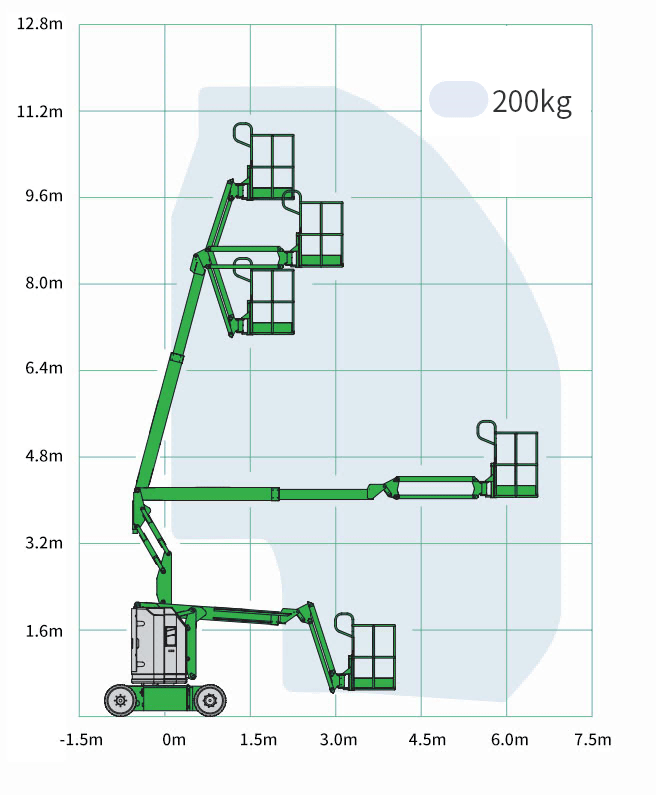

| Max. Working height | 17.7m |

| Max. Platform height | 15.7m |

| Max. up and over clearance | 7.3m |

| Max. Working radius | 8.9m |

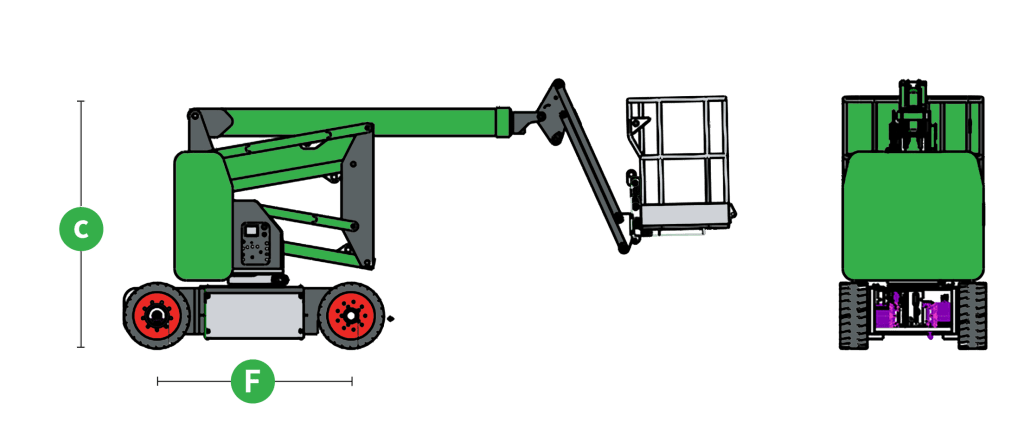

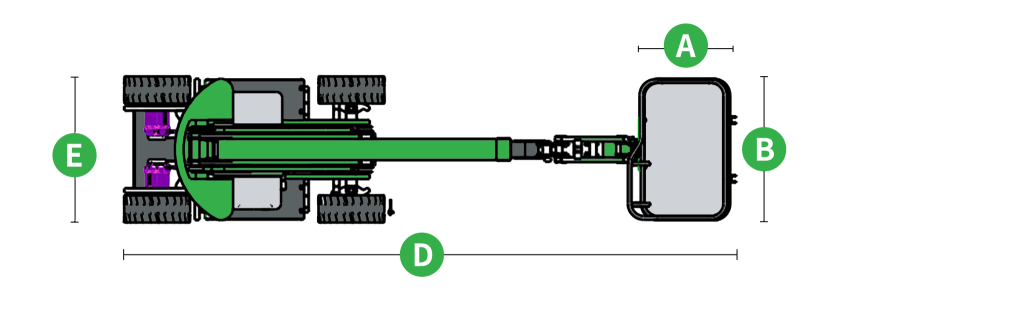

| Ⓐ Platform width | 0.76m |

| Ⓑ Platform length | 1.4m |

| Ⓒ Height – stowed | 2.0m |

| Ⓓ Length – stowed | 7.2m |

| Ⓔ Width | 1.9m |

| Ⓕ Wheelbase | 2.0m |

| Ground clearance – center | 0.25m |

| Productivity | |

| Max. Lift capacity | 230kg |

| Number of platform occupants | 2 |

| Platform rotation | ±80° |

| Turntable rotation | 355° |

| Vertical jib rotation (up/down) | ±70° |

| Drive speed – stowed | 5.1km/h |

| Gradeability – stowed | 30% |

| Max. Working angle (Tilt sensor activation) | 3° |

| Turning radius (outside) | 3.45m |

| Drive and steer | 2×2 |

| Weight | 6630kg |

| Power | |

| Battery | 48V/320Ah |

| Control voltage | 24V |

| Pump motor | 4kw |

| Drive motor | 3.3kw |

Features

The product is lightweight and energy-saving, and has compact design with excellent battery life.

Σ-shaped boom with compact structure and flexible extension can realize vertical lifting and horizontal extension, and has strong obstacle-surpassing ability.

160° rotatable platform provides a larger working range, while the narrow turntable with compact layout improves work efficiency.

The platform control panel is PG and Bosch Rexroth brand, which is the same as the ground control. User-friendly design with safety factors considered ensures a reliable work performance.

International brand drag chain of the telescopic jib provides safety protection and guiding capabilities for the cables inside the booms and prolongs the service life of the cables.

Equipped with solid tires, skid-proof and explosion-proof with longer lifetime, providing a stable and labor-saving operation.

Videos

Diagram

Other Boom Lifts

FAQ

Custom Options

Customize Your Lifts

Specifically sized, configured, mobile, high-cycle, or automated – when you need a lift to perform a specific function, we have the materials, components, and design techniques to produce a one-of-a-kind lifting solution for your application.

Lift Product Videos

Customized Cases

Autonomous Vehicle Testing Calibration Rotating Platform

Scissor-Style 316L Stainless Steel Underwater Lifting Platform

Efficient and Stable Hydraulic Lift for Loading and Unloading Challenges in the Tobacco Industry

3-Ton Chain Flip Machine For Double Screw Pump

304 Stainless Steel Cargo Lift for Pharmaceutical Raw Material Handling

Reciprocating Lift Designed for Transporting Cat Litter

Efficient Vertical Reciprocating Lift: Tailored Solution for Bulk Transport in the Lithium Battery Industry

316 Stainless Steel Lift Platform: Automated Transport Solution for Breweries

Automated Goods Lift for Unmanned Warehouses

Lift Platform For Graphite Material Company

Goods Lift For Water Purification Technology Company

Cargo Unloading Platform Flip Plate Equipment

| LIFT CAPACITY | |

|---|---|

| PLATFORM LENGTH | 1 – 3 m |

| PLATFORM WIDTH | ≤ 1 m |

| TRAVEL DISTANCE | > 11 m |