Ponte de elevação vertical

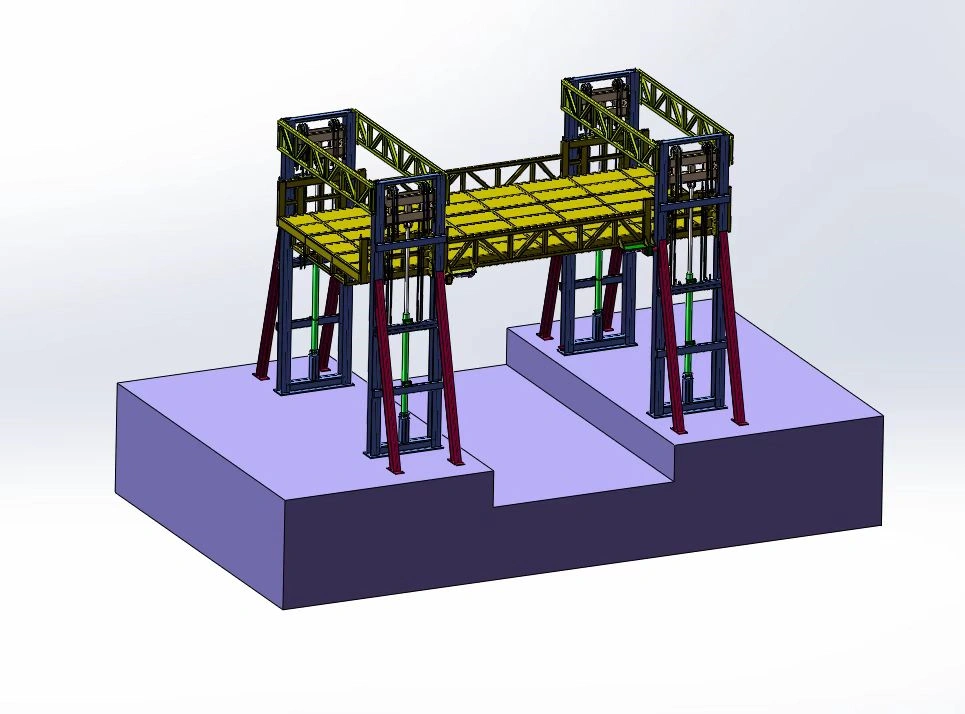

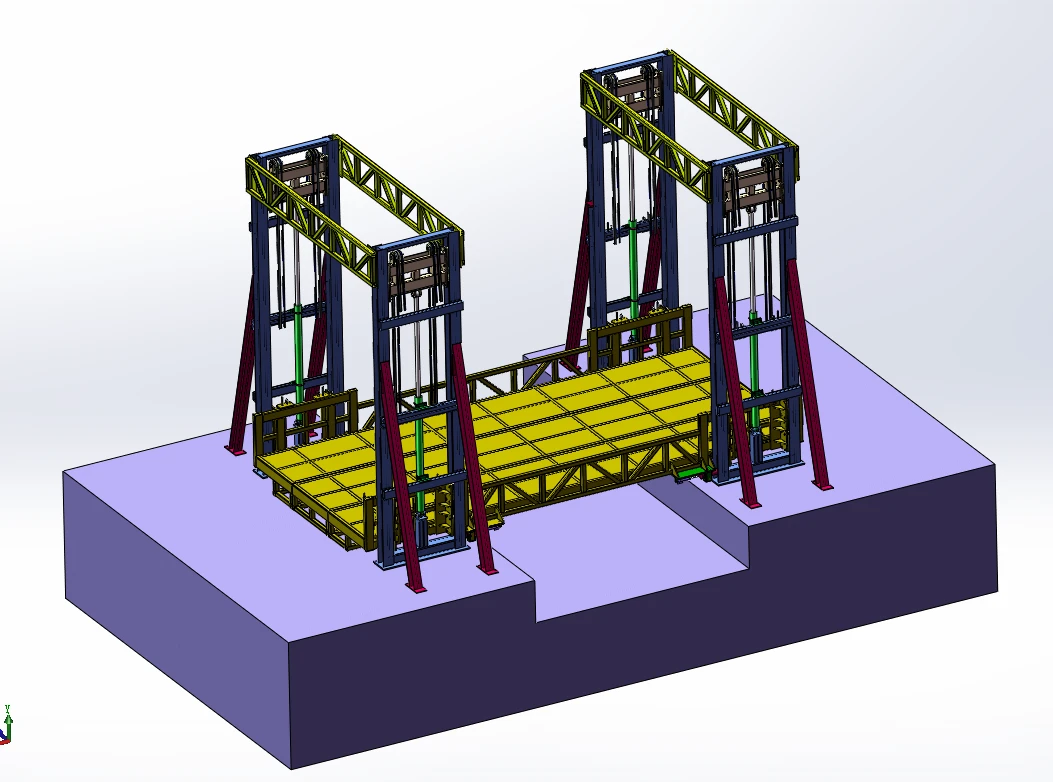

A ponte elevatória hidráulica apresenta recursos de elevação flexíveis para acomodar várias alturas de carga e descarga, garantindo um fluxo suave de matérias-primas e produtos acabados. Com um tamanho de plataforma de 4800*16000 mm, ela oferece amplo espaço para a atracação de vários veículos de transporte.

Modelos e especificações

| Modelo do produto | SJD36.0-4.2 | SJD36.0-4.2 |

|---|---|---|

| Tamanho da plataforma: | 4800*10000mm | 4800*16000mm |

| Tamanho do espaço necessário: | 5600*10000mm | 5600*16000mm |

| Direção de entrada/saída | Até 4800 mm | |

| Estações de ancoragem | 2/2 | |

| Altura de deslocamento: | 4200 mm | |

| Velocidade: | 2-4m/min | |

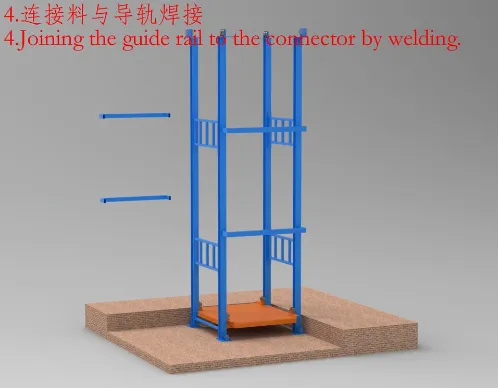

| Estrutura | 4 cilindros, 8 colunas | |

| Tamanho da base | 5600*1500*10mm | |

| Nivelamento | Mecanismo de nivelamento | |

| Método de controle | Manual e remoto | |

| Guarda-corpo da plataforma | 10000*1200mm | 15000*1200mm |

Base Industrial Zhongwei Indonesia North Morowali: Aprimorando a produção de níquel de baixo teor e a eficiência do processamento com uma ponte elevatória hidráulica

A ponte elevatória hidráulica para veículos, localizada na Base Industrial Zhongwei Indonesia North Morowali, foi projetada especificamente para o transporte de minerais, aumentando a segurança e a conveniência. Esse sistema de ponte elevatória consiste em quatro dispositivos de elevação hidráulica, sendo que três unidades têm uma plataforma de 4,8 m x 10 m e uma unidade mede 4,8 m x 16 m, cada uma capaz de suportar uma carga de até 36 toneladas e atingir uma altura máxima de elevação de 4,2 metros.

Os principais recursos dessa ponte elevatória incluem:

- Alta capacidade de carga: Cada ponte elevatória pode suportar com segurança 36 toneladas, o que a torna adequada para caminhões pesados e transporte de minerais.

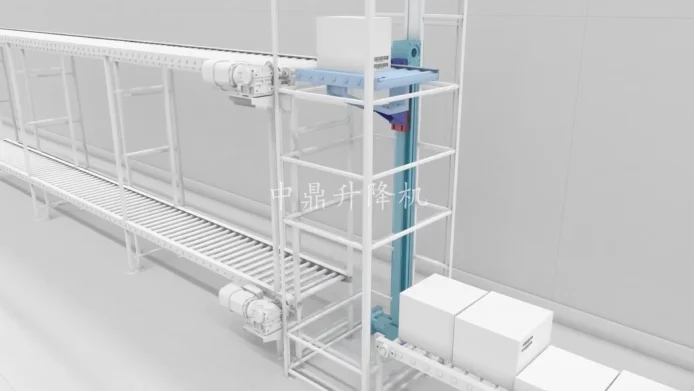

- Levantamento e abaixamento flexíveis: Com opções de controle manual e remoto, é fácil de operar e pode responder rapidamente às necessidades de transporte.

- Controle inteligente: Equipado com codificadores, válvulas proporcionais e sistemas PLC, ele garante o controle preciso da altura e a elevação sincronizada, minimizando os erros operacionais.

- Projeto de segurança: A ponte elevatória permanece em uma posição elevada para evitar colisões com os veículos de transporte abaixo, garantindo a segurança do transporte.

- Estrutura durável: Construído com um design de 4 cilindros e 8 colunas, ele é robusto e adequado para ambientes de trabalho adversos.

- Configuração eficiente do espaço: A base de cada unidade mede 5.600 mm x 1.500 mm x 10 mm, permitindo uma operação eficiente em espaços confinados.

Esse sistema de ponte elevatória não apenas melhora a eficiência do transporte de minerais, mas também reduz significativamente os riscos operacionais por meio de um projeto inteligente e seguro, fornecendo suporte confiável para as operações de mineração.

Vídeos relacionados

Estudos de caso relacionados

| CAPACIDADE DE ELEVAÇÃO | |

|---|---|

| COMPRIMENTO DA PLATAFORMA | > 11 m |

| LARGURA DA PLATAFORMA | 4 - 5 m |

| DISTÂNCIA DE VIAGEM | 3 - 5 m |